Top 10 Best Truck Cranes for Heavy Lifting in 2026?

Truck cranes are essential for heavy lifting tasks. In 2026, the demand for efficient and reliable truck cranes has risen sharply. These machines combine mobility and power, making them a perfect choice for various construction sites.

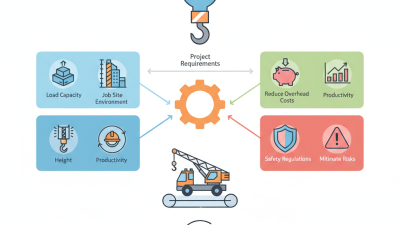

Choosing the right truck crane can be overwhelming. Many models come with unique features and specifications. It's important to consider lifting capacity, reach, and stability. Not all cranes suit every job, and selecting the wrong one can lead to inefficiency.

In this guide, we will explore the top 10 best truck cranes available in 2026. Each truck crane offers different benefits and potential challenges. Understanding these aspects can help you make an informed choice. Let’s dive into the outstanding options for heavy lifting this year.

Overview of Truck Cranes: What to Look for in 2026

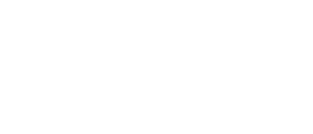

When selecting truck cranes for heavy lifting in 2026, several key features are vital.

Load capacity stands at the forefront.

Typical models can lift between 15 to 80 tons.

Understand how much weight your projects demand.

Stability must also be prioritized.

A crane that wobbles under load can lead to disasters.

Look for features like outriggers and a wide wheelbase.

Safety technology continues to evolve.

Most new models incorporate advanced load monitoring systems.

These systems prevent overload, reducing accident risk.

Data from the International Crane Safety Report suggests that up to 30% of crane accidents stem from overloading.

Be cautious and informed.

Also, consider ease of maintenance.

Truck cranes require regular checks.

Choose one with accessible parts.

Frequent downtime for repairs can be costly.

In a 2025 survey, maintenance issues accounted for 15% of operational delays.

Evaluate all aspects carefully.

Your choice impacts not just efficiency but overall project safety and cost.

Top Features to Consider in Heavy Lifting Truck Cranes

When considering truck cranes for heavy lifting, safety features are paramount. Look for cranes equipped with load monitoring systems. These systems help prevent overload situations. Additionally, check for stabilizers that enhance crane stability during operations. A solid foundation is crucial for effective lifting without accidents.

Another essential aspect is the lifting capacity. It varies greatly among models. Make sure to assess the maximum load each crane can handle. The reach and height capabilities matter too. Ensure that the crane can access various worksite heights. Clear visibility from the driver's seat can’t be overlooked, either. Proper sightlines reduce blind spots and enhance safety.

Durability is important. Truck cranes work in harsh conditions. Materials used in construction will affect their lifespan. Regular maintenance should also be considered. Even the best cranes can have issues over time. Reflect on their ease of maintenance. If a crane is hard to repair, it can lead to costly downtimes.

Top 10 Best Truck Cranes for Heavy Lifting in 2026

| Model | Maximum Load Capacity (tons) | Maximum Reach (meters) | Weight (tons) | Rotational Capacity (degrees) | Price (USD) |

|---|---|---|---|---|---|

| Model A | 30 | 20 | 15 | 360 | 150,000 |

| Model B | 25 | 18 | 12 | 360 | 120,000 |

| Model C | 35 | 22 | 17 | 360 | 180,000 |

| Model D | 40 | 25 | 20 | 360 | 210,000 |

| Model E | 50 | 30 | 25 | 360 | 300,000 |

Comparative Analysis of the Leading Truck Crane Brands

When analyzing the top truck cranes for heavy lifting, several key factors emerge. Lifting capacity is crucial. The best models can lift over 50 tons. Durability also matters, especially in tough working conditions. These cranes should withstand harsh weather and rough terrain. A solid chassis design enhances stability, ensuring safe operations.

Customer feedback highlights reliability as a concern. Users often report issues with complicated controls. Some cranes have a steep learning curve. Ease of use is essential for operators. Maintenance routines can be cumbersome. Frequent checks and repairs can affect productivity. It is important for manufacturers to address these issues.

Another point to consider is versatility. Many cranes can adapt to different tasks. Some models excel in urban environments, while others shine in rural areas. However, not all designs can meet varying needs. A truck crane that performs well in one setting may struggle in another. This inconsistency poses challenges for project managers. Evaluating these factors helps identify the best options in the competitive truck crane market.

Applications of Truck Cranes in Various Industries

Truck cranes play a vital role across many industries. Their versatility allows them to perform heavy lifting tasks efficiently. Construction sites benefit significantly from their use. Cranes lift steel beams, large equipment, and precast concrete elements. They make complex construction projects manageable.

In the oil and gas sector, truck cranes are indispensable. They transport materials and assist in equipment installation. Their mobility allows for quick access to remote locations. This speed can significantly reduce downtime.

When choosing a truck crane, consider the application. Not all cranes suit every task. Some may struggle with weight limits. Others may not fit into tight spaces. Check the load capacity before purchasing.

Keep your truck crane well-maintained. Regular checks can prevent breakdowns. Ensure to follow safety guidelines during operations. This safeguards operators and job sites. Always review specifications carefully. A wrong choice can lead to inefficiencies and extra costs.

Top 10 Best Truck Cranes for Heavy Lifting in 2026

Future Trends in Truck Crane Technology and Design

The future of truck crane technology is promising. Industry reports predict a shift towards more automated systems. Automation can enhance precision in heavy lifting. Advanced sensors and AI algorithms aid in real-time load monitoring. According to a recent study, automated systems could reduce operation costs by up to 25%.

Moreover, sustainability is becoming a central focus. New designs prioritize fuel efficiency and electric hybrid technologies. A forecast by market analysts shows that eco-friendly cranes will comprise 30% of the market by 2027. However, transitioning to sustainable models may pose challenges. Many operators are hesitant to invest in new tech.

Additionally, safety features are evolving. Innovations like real-time hazard detection systems are emerging. These systems can alert operators of potential risks, thus preventing accidents. However, integrating this technology into existing cranes may require significant modifications. Training will also be essential to ensure smooth adoption. The industry's path towards modernization may be complex, but it holds substantial potential.

Related Posts

-

10 Best Types of Construction Cranes for Efficient Project Management

-

10 Essential Tips for Operating Truck Cranes Safely and Efficiently

-

What Is Crane Rentals? Understanding Costs, Types, and Benefits of Renting Cranes

-

How to Choose the Right Boom Truck Crane Rental for Your Project Needs

-

What is Crane Truck Rental and How Does it Work?

-

How to Choose the Right All Terrain Crane for Your Project in 2026?